Shredders

1500 TH

Industrial multi-shift machines for highest briquette quality and throughput demands.

Balers

BERGMANN WASTE SOLUTIONS

Nothing is more expensive than storing and transporting air. Needless hollow spaces are the result of uncompacted waste. Not only do containers and storage spaces bulge, but their costs also quickly spill over! BERGMANN has been setting standards in the waste disposal industry for over 50 years. BERGMANN products and system solutions stand for longevity, reliability and ease of maintenance.With sophisticated BERGMANN products > Increase the load capacity of containers > Reduce the number of disposal journeys > Use less space for container storing areas and waste storage > Reduce your logistics costs > Reduce your labour costs

Balers

CK 101

CK101 is designed for clients with small amounts of waste. The minimum floor space and the single phase power supply makes it very easy to install and to use.

Show technical data >| Modelis | CK51 | CK101 | CK151 | CK250 |

|---|---|---|---|---|

| Dimensions, AxPxI (mm) | 2220x830x785 | 2410x940x940 | 2460x1230x990 | 2440x1720x950 |

| Baler weight (kg) | 375 | 450 | 700 | 1100 |

| Feeding opening, IxP (mm) | 550x715 | 710x815 | 540x1090 | 590x1040 |

| Pressing force (t). | 4 | 5 | 10 | 16 |

| Cycle time (-i) | 42 | 52 | 55 | 55 |

| Noise level (dB) | 70 | 70 | 60 | 60 |

| Bale size, AxPxI (mm) | 600x710x510 | 600x740x700 | 2440x1720x950 | 1965x1390x925 |

| Cardboard bale weight (kg) | 70 | 80-110 | 150-180 | 250-280 |

Balers

CK 300VX

The CK300VX is designed for retail stores and factories to process large amounts of waste. Due to the low height of the press, it is easy to transport and install.

Show technical data >| Modelis | CK300 | CK500 | CK100vx |

|---|---|---|---|

| Pressure power | 30 | 50 | 10 |

| Power | 4 KW | 5.5 KW | 4KW |

| feed | 1 x 230V, 50Hz | 415V | 3 x 415V, 50Hz |

| Loading slot | 530×1125 | 610x1170 | 675×715 |

| Cycle duration | 35 s | 55 s | 35 s |

| Noise level (dBA) | 60 dBA | dBA | 60 dBA |

| Device dimensions (H x W x D mm) | 1995x1875x1030 | 3060x1800x1200 | 1955 x 1450 x 1300 |

| Device weight | 1440 Kg | 2200 Kg | 825 Kg |

Balers

CK 450HFEPC

Excellent height for hand loading materials. Vertical binding.

Show technical data >| Modelis | CK450HFEPC | CK600HFEPC |

|---|---|---|

| Compression power | 60 | 60 |

| Motor | 11/15/22 kW | 15/22 kW |

| Cycle(s) | 60/42/30 s | 45/30 s |

| Noise level | 80 dBA | 80 dBA |

| feed | 3x415V/50Hz | 3x415/50Hz |

| Package size (LxWxH) | 900-1300x1100x750 mm | 1200x1500x750x1080 mm |

| Loading slot (IxP) | 1480x1040 | 1500x720 |

| Device dimensions (LxWxH) | 7200x1600x2400 mm | 7450x1410x2630 mm |

| Weight (kg) | 7000 kg | 6250 kg |

Balers

CK 500V

The CK500V is best suited for areas with a large amount of waste, such as large retail stores, factories and waste processors. The robust design of the CK500V allows users to press materials such as cardboard, plastic, hard plastic, e-waste and PET.

Show technical data >| Model | CK300 | CK500 | CK100vx |

|---|---|---|---|

| Pressing force | 30 | 50 | 10 |

| Motor | 4 KW | 5.5 KW | 4KW |

| Power supply | 1 x 230V, 50Hz | 415V | 3 x 415V, 50Hz |

| Feed opening | 530×1125 | 610x1170 | 675×715 |

| Cycle | 35 s | 55 s | 35 s |

| Noise level (dBA) | 60 dBA | dBA | 60 dBA |

| Baler size (H x L x P mm) | 1995x1875x1030 | 3060x1800x1200 | 1955 x 1450 x 1300 |

| Weight | 1440 Kg | 2200 Kg | 825 Kg |

Balers

CK 51

The CK51 is the perfect solution for space-constrained work environments. This small vertical baler compresses a bale weighing up to 70 kg, which is easy to transport with a trolley.

Show technical data >| Model | CK51 | CK101 | CK151 | CK250 |

|---|---|---|---|---|

| Measurements LxWxH (mm) | 2220x830x785 | 2410x940x940 | 2460x1230x990 | 2440x1720x950 |

| Device weight (kg) | 375 | 450 | 700 | 1100 |

| Loading slot IxP (mm) | 550x715 | 710x815 | 540x1090 | 590x1040 |

| Pressing power (t) | 4 | 5 | 10 | 16 |

| Cycle(s) | 42 | 52 | 55 | 55 |

| Noise level (dB) | 70 | 70 | 60 | 60 |

| Bundle size LxWxH (mm) | 600x710x510 | 600x740x700 | 2440x1720x950 | 1965x1390x925 |

| Cardboard bundle weight (kg) | 70 | 80-110 | 150-180 | 250-280 |

Balers

CK 600HFEPC

Recommended for PET bottles, aluminum cans, cardboard.

Show technical data >| Model | CK450HFEPC | CK600HFEPC |

|---|---|---|

| Compression power | 60 | 60 |

| Motor | 11/15/22 kW | 15/22 kW |

| Cycle(s) | 60/42/30 s | 45/30 s |

| Noise level | 80 dBA | 80 dBA |

| feed | 3x415V/50Hz | 3x415/50Hz |

| Package size (LxWxH) | 900-1300x1100x750 mm | 1200x1500x750x1080 mm |

| Loading slot (IxP) | 1480x1040 | 1500x720 |

| Device dimensions (LxWxH) | 7200x1600x2400 mm | 7450x1410x2630 mm |

| Weight (kg) | 7000 kg | 6250 kg |

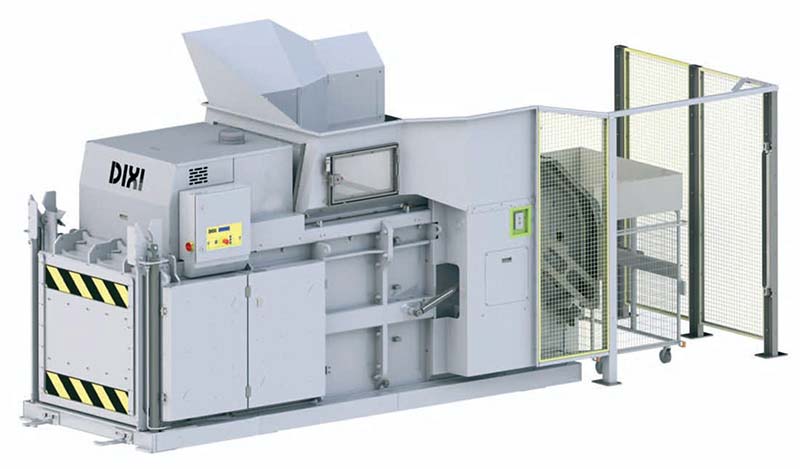

Balers

DIXI 25

The DIXI 25 S / 30 S model series with a pressing force of 25 or 30 tons falls into the professional class and allows you to press bales weighing up to 360 kg.

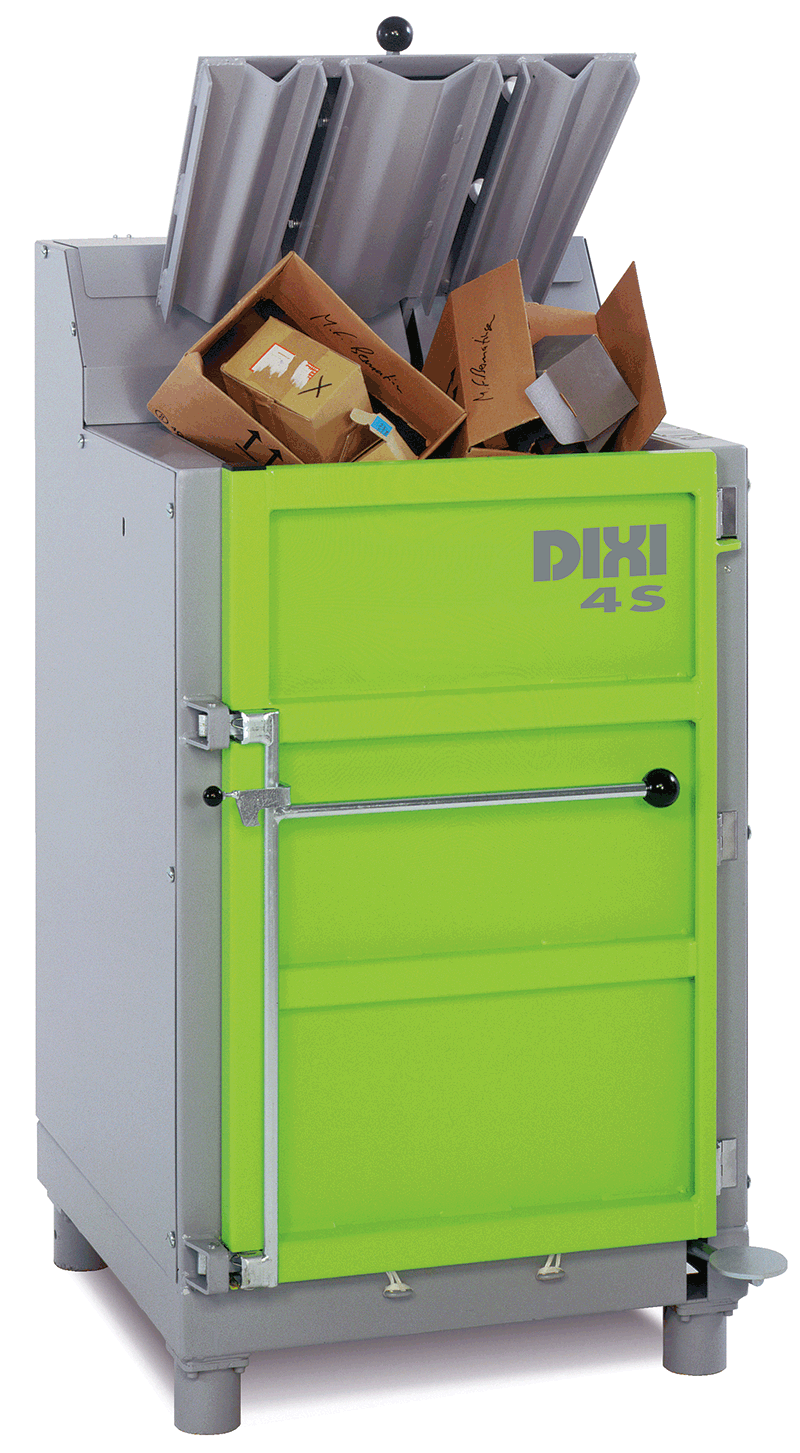

Balers

DIXI 4S

Proven, attractively priced hydraulic compact press.

Balers

DIXI 5S-K

The DIXI 5 S-K hydraulic press system model is delivered as a single-chamber press - it can be expanded with additional pressing chambers upon request.

Balers

DIXI 60S

The DIXI 60 S model series, with a minimum height of 2.17 m and a pressing force of 60 t, makes the press an ideal partner for all volume reduction processes. This much capacity in such a compact form factor is unprecedented.

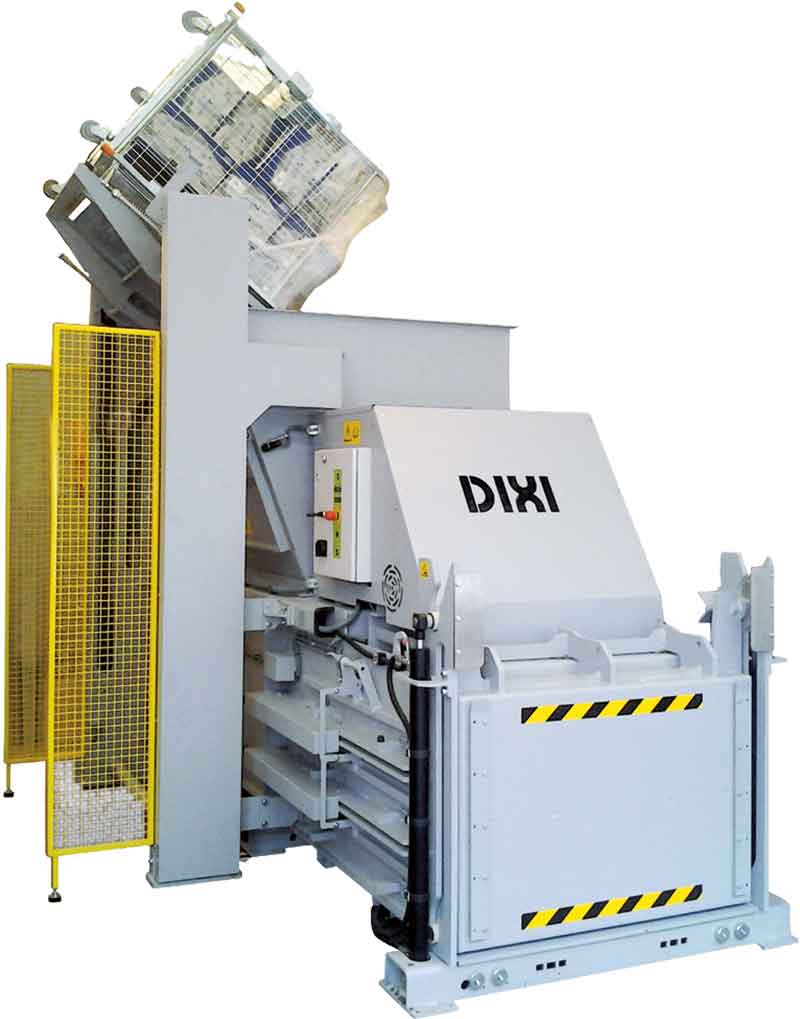

Balers

DIXI 60SLD/SLS

Semi-automatic press system with 60 tons of force for economical volume reduction

Balers

DIXI 80SLD

Semi-automatic baler with 80 t pressing power for economical volume reduction.

Compactors

HEGER Tigras 130/400/400

The Heger THE TIGER line uses an innovative technology that allows extremely efficient compression of bulky waste foam EPS (Styropor®) into easy-to-manage, stackable blocks - without re-expansion. The extreme volume reduction achieved in this way (by a ratio of 40:1) not only significantly saves transportation and disposal costs, but also the produced blocks can be recycled as raw material, thus contributing to rapid amortization.

Show technical data >| The Tiger | Productivity(kg/h) | Compression (kg/m) | Volume per day (kg) |

|---|---|---|---|

| 130 B | 10-20 | 200-350 | 40-80 |

| 130 S | 10-20 | 200-350 | 40-80 |

| 130 T | 10-15 | 200-350 | 40-60 |

| 200 B | 40-60 | 200-350 | 100-400 |

| 200 S | 40-60 | 200-350 | 100-400 |

| 200 T | 40-60 | 200-350 | 50-200 |

| 300 B | 80-120 | 200-350 | 200-800 |

| 300 S | 80-120 | 200-350 | 200-800 |

| 400 B | 150-200 | 200-350 | 400-1500 |

| 400 S | 150-200 | 200-400 | 600-1500 |

| COMPRESSION-Line 200 | 40-60 | 250-350 | 200-400 |

| COMPRESSION-Line 300 | 80-120 | 250-350 | 400-800 |

| COMPRESSION-Line 400 | 150-200 | 250-350 | 600-1500 |

Shredders

Neuenhauser TARGO 3000 XD

The TARGO 3000 XD weighs an impressive 35 tons. The concentrated power of this heavyweight champion is expressed in two letters: XD stands for "eXtra Duty", which means "extra strong". Without a doubt, this mobile shredder is an extremely strong representative of its class. Designed specifically for big challenges.

Show technical data >| Chassis | Tracked chassis, two speeds |

| Weight | 35,000 kg |

| Measurements | I/W/H 7,390 / 2,780 / 3,330 mm |

| Crushing chamber: | |

| Length | 3,000 mm |

| Diameter | 600 mm |

| Turns | max. 34 rpm |

| "Teeth" width | 60 mm |

| "Teeth" length | 174 mm |

| The number of "teeth" in the chamber | 21 |

| Combs: | |

| Length | 3,000 mm |

| Width | 60 mm |

| The number is in the camera | 20 |

| Discharge Conveyor: | |

| Width | 1,200 mm |

| Length | 5,040 mm |

| Additional conveyor length | 7,500 mm |

| Belt speed | max. 4,2 m/s |

| Assembly conveyor:` | |

| Width | 1,000 mm |

| Length | 3,335 mm |

| Belt speed | max. 2,6 m/s |

| Motor | |

| Engine type | Diesel |

| Emissions standard | The highest classes of existing standards |

| Power | 375 kW |

| Fuel tank | 500 litre |

| Engine displacement | 13 litre |

Shredders

POWERLINE 1500

Powerful waste shredders for maximum productivity.

Shredders

PRE CUT 2000

Robust and low-maintenance primary shredders that meet the highest requirements.

Shredders

PUEHLER A.200

This series contains label presses, can presses, recycling and packaging presses and rework presses.

Shredders

ROCKSTER R1100S Smūginis smulkintuvas

The R1100S mobile shredder is based on the Rockster hydraulic concept and guarantees profitable processing of asphalt, concrete and any construction waste. The powerful rotor installed in the ROCKSTER RS1100S shredder allows efficient work with stones as well.

Show technical data >| Hole: | 1100 x 720 mm / 44" x 29" |

| Rotor: | 4 hammers |

| Grinding gear: | Hydrostatic |

| Rotor speed: | Adjustable without steps |

| Moving beams: | 2 (individually adjustable) |

| Gap adjustment: | Fully hydraulic |

| Gear: | Tier 3A - Stage IIIA / Tier 4 Final / Stage V engine |

| Sifting: | Vibrating (Avoid jams) |

| Transport dimensions and weight R1100S: | Length: 13,60 m / 44'8" Width: 2,75 m / 9'1" Height: 3,20 m / 10'6" Weight: 32,90 t / 72,600 lbs |

Shredders

ROCKSTER R800

The JAW Mobile Crawler Crusher R800 is the ideal solution for any application with the highest demands on wearing parts. In addition to construction and demolition (CD) recycling, this robust crusher can handle the heaviest aggregates under the most abrasive conditions.

Show technical data >| Hole: | 800 x 500 mm / 36" x 29" |

| Grinding ratio: | 1:8 |

| Grinding gear: | Hydrostatic |

| Gap adjustment: | Fully hydraulic |

| Gear: | Tier 3A - Stage IIIA / Tier 4 Final - Stage IV / Stage V |

| Sifting: | Vibrating (avoid jams) |

| Transport dimensions and weight: | Length: 9,60 m / 31'6" Width: 2,50 m / 8'3" Height: 3,20 m / 10'6" Weight: 25,70 t / 56,700 lbs |

Sorters

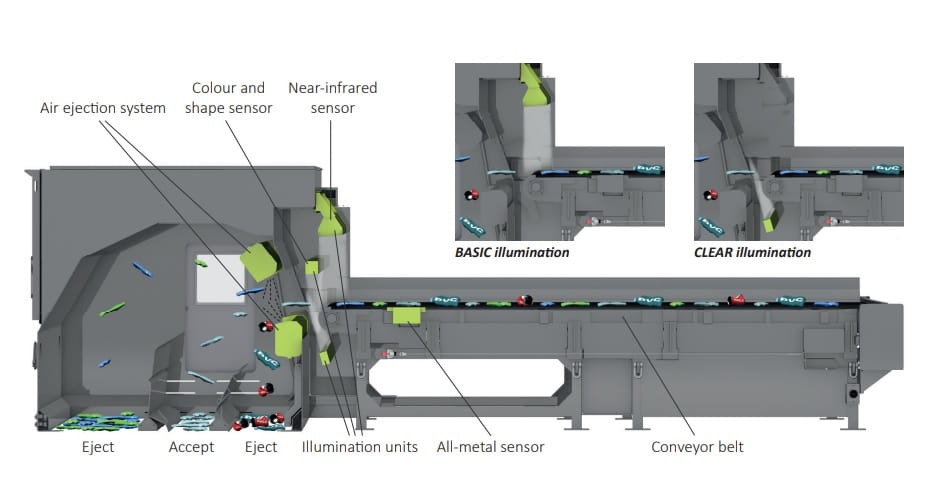

Sesotec VARISORT

SESOTEC's smart technologies are designed for detection of inappropriate objects, material sorting and analysis.Technology enables our customers to create safe, efficient manufacturing processes that comply with regulations.Industries:Food industry - determination of physical pollution in food production;Plastic industry - detection of unsuitable materials in the plastic industry;Processing - purification of material;Product categories:metal detection systems;sorting systems;magnetic systems;analysis systems;

Screeners

SPALECK Flip-Flow sijotuvas

If optimal screening performance, quality and screening result are important to you, the SPALECK Flip-Flow sieving technology is just for you. Flip-Flow sieving machines must be reliable and powerful when processing waste. With our fine material sieving machines, you optimize the processing of the sieving material. Machine performance is a guarantee of the good performance of all your processing equipment

Press containers

Tehnix DPKH/DPKP 32 m3

The pre-container (Tehnix type) is a modern device for the collection and compression of municipal waste, paper, cardboard, plastic and other secondary raw materials. It is an ideal solution for your company, city, town, hospital, gas station, hotels, camps, industry and shopping centers. Once in use, the pre-container will save a lot of money in terms of transport and reduce the quantities at disposal sites.

Show technical data >| MODEL | DIMENSIONS | Compressive power (kN) | Power (kW) (kW) | ||

| LENGTH (mm) | WIDTH (mm) | HEIGHT (mm) | |||

| PKH/PKP 5 m3 | 3780 | 1900 | 1655 | 320 | 4 / 5,5 |

| PKH/PKP 7,5 m3 | 4370 | 2115 | 2055 | 320 | 4 / 5,5 |

| PKH/PKP 10 m3 | 4770 | 2115 | 2055 | 320 | 4 / 5,5 |

| PKH/PKP 14 m3 | 5950 | 2035 | 2235 | 320 | 5,5 / 7,5 |

| PKH/PKP 16 m3 | 5930 | 2530 | 2525 | 320 | 5,5 / 7,5 |

| PKH/PKP 20 m3 | 6680 | 2530 | 2525 | 320 | 5,5 / 7,5 |

| DPKH/DPKP 20 m3 | 4500 | 2360 | 2680 | 320 | 5,5 / 7,5 |

| DPKH/DPKP 32 m3 | 6430 | 2360 | 2680 | 350 | 5,5 / 7,5 |

Press containers

Tehnix PKH/PKP 10 m3

The pre-container (Tehnix type) is a modern device for the collection and compression of municipal waste, paper, cardboard, plastic and other secondary raw materials. It is an ideal solution for your company, city, town, hospital, gas station, hotels, camps, industry and shopping centers. Once in use, the pre-container will save a lot of money in terms of transport and reduce the quantities at disposal sites.

Show technical data >| MODEL | DIMENSIONS | Compressive power (kN) | Power (kW) | ||

| LENGTH (mm) | WIDTH (mm) | HEIGHT (mm) | |||

| PKH/PKP 5 m3 | 3780 | 1900 | 1655 | 320 | 4 / 5,5 |

| PKH/PKP 7,5 m3 | 4370 | 2115 | 2055 | 320 | 4 / 5,5 |

| PKH/PKP 10 m3 | 4770 | 2115 | 2055 | 320 | 4 / 5,5 |

| PKH/PKP 14 m3 | 5950 | 2035 | 2235 | 320 | 5,5 / 7,5 |

| PKH/PKP 16 m3 | 5930 | 2530 | 2525 | 320 | 5,5 / 7,5 |

| PKH/PKP 20 m3 | 6680 | 2530 | 2525 | 320 | 5,5 / 7,5 |

| DPKH/DPKP 20 m3 | 4500 | 2360 | 2680 | 320 | 5,5 / 7,5 |

| DPKH/DPKP 32 m3 | 6430 | 2360 | 2680 | 350 | 5,5 / 7,5 |

Press containers

Tehnix PKH/PKP 20 m3

The pre-container (Tehnix type) is a modern device for the collection and compression of municipal waste, paper, cardboard, plastic and other secondary raw materials. It is an ideal solution for your company, city, town, hospital, gas station, hotels, camps, industry and shopping centers. Once in use, the pre-container will save a lot of money in terms of transport and reduce the quantities at disposal sites.

Show technical data >| MODEL | DIMENSIONS | Compressive power (kN) | Power (kW) | ||

| LENGTH (mm) | WIDTH (mm) | HEIGHT (mm) | |||

| PKH/PKP 5 m3 | 3780 | 1900 | 1655 | 320 | 4 / 5,5 |

| PKH/PKP 7,5 m3 | 4370 | 2115 | 2055 | 320 | 4 / 5,5 |

| PKH/PKP 10 m3 | 4770 | 2115 | 2055 | 320 | 4 / 5,5 |

| PKH/PKP 14 m3 | 5950 | 2035 | 2235 | 320 | 5,5 / 7,5 |

| PKH/PKP 16 m3 | 5930 | 2530 | 2525 | 320 | 5,5 / 7,5 |

| PKH/PKP 20 m3 | 6680 | 2530 | 2525 | 320 | 5,5 / 7,5 |

| DPKH/DPKP 20 m3 | 4500 | 2360 | 2680 | 320 | 5,5 / 7,5 |

| DPKH/DPKP 32 m3 | 6430 | 2360 | 2680 | 350 | 5,5 / 7,5 |

Shredders

TH514

Robust all-rounders with proven clamp technology for medium throughputs.

Conveyor systems

Transportation of secondary raw materials to pressing equipment. Conveyor type – according to each individual need.

Shredders

WLK 1000/1500

Designed for high performance and suitable for shredding almost all types of waste - especially for: Plastics. Plastic ingots, pipes, scrap cars, blown materials (PE/PET/PP bottles, buckets, pallets and containers), as well as paper, cardboard, wood and light metals.

Show technical data >| The model | WLK-4 | WLK-10 | WLK-15 | WLK-20 |

|---|---|---|---|---|

| Loading opening (mm) | 600 × 1050 | 1000 x 1200 | 1500 × 1500 | 2000 × 1500 |

| Shaft Ø (mm) | 270 | 368 | 368 | 368 |

| Shaft length (mm) | 600 | 1000 | 1500 | 2000 |

| Spindle speed (rpm) | 100 | 85 | 85 | 85 |

| Power (kW) | 18.5 / 22 | 37/45/55/75 | 55/75/90 | 110/132 |

| Shaft knives | 28 | 52 | 82 | 110 |

| Weight (kg) | 1300 | 3500 | 6500 | 9000 |

| Screen size (mm) | 15-40 | 15-100 | 15-100 | 15-100 |

Shredders

WLK 4/6s/800

Universal industrial shredders with many options.

Show technical data >| The model | WLK-4 | WLK-10 | WLK-15 | WLK-20 |

|---|---|---|---|---|

| Loading opening (mm) | 600 × 1050 | 1000 x 1200 | 1500 × 1500 | 2000 × 1500 |

| Shaft Ø (mm) | 270 | 368 | 368 | 368 |

| Shaft length (mm) | 600 | 1000 | 1500 | 2000 |

| Spindle speed (rpm) | 100 | 85 | 85 | 85 |

| Power (kW) | 18.5 / 22 | 37/45/55/75 | 55/75/90 | 110/132 |

| Shaft knives | 28 | 52 | 82 | 110 |

| Weight (kg) | 1300 | 3500 | 6500 | 9000 |

| Screen size (mm) | 15-40 | 15-100 | 15-100 | 15-100 |

Shredders

WNZ 200-600

Compact and fast rotating secondary shredders for regular output.

Shredders

ZM 30/50

Low rpm and quiet rotating four shaft shredders for aggressive feeding.

Show technical data >| The model | ZM 30 | ZM 40 | ZM 50 |

|---|---|---|---|

| Pakrovimo anga (mm) | 1000 × 1250 | 1300 × 1400 | 1500 × 1400 |

| Shaft Ø (mm) | 235 | 280 | 280 |

| Shaft length (mm) | 480 | 760 | 960 |

| Spindle speed (rpm) | 25 | 25 | 25 |

| Power (kW) | 2 x 7.5 / 2 “× 11 | 2 × 15 / 18,5 × 2/2 × 22 | 2 × 15 / 18,5 × 2/2 × 22/2 × 30 |

| Shaft knives | 23 | 25 | 47 |

| Weight (kg) | 1300 | 2500 | 3000 |

| Connection diameter (mm) | 200 | 200 | 200 |

| Screen size (mm) | 20-40 | 20-40 | 20-40 |